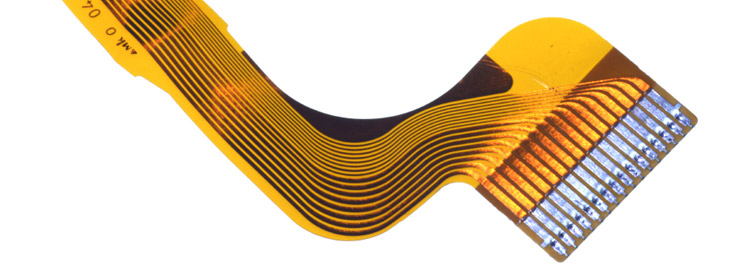

Flexible & Flex-Rigid PCB

Flexible Printed Circuits

Flexible printed circuits can offer a great solution to connection between rigid PCBs with a reliable and repeatable product. They have so many applications it would be impossible to list them all here. They offer a third dimension to connect between rigid boards or to interface between a board and a remote device, for example a sensor or a speaker microphone as in a mobile phone. They offer a lightweight solution, about half the weight of a rigid or a cable harness, to interconnections.

They are robust and can be flexed numerous times without any degradation to the product. In a well designed dynamic situation, the flex can go through millions of cycles, a common example would be on an inkjet printer head. They also have the advantage of absorbing shock so in a small device, for example a phone, they can take an impact without disconnecting the circuits.

They are also used to mount LEDs for applications such as down lighters on kitchen benches, outside deck lighting. This would be in a strip form. Safety lights in transport systems, for example planes, trains and boats all utilise LED flexi strip for the emergency exit routes.

Although more expensive than a standard PCB, the right design in the right application could save, weight and time in assembly, coupled with the reliability which makes flexible printed circuits a worthwhile consideration. Variations are mainly base and overlay thickness, typically 0.001” to 0.002”, copper thickness, single or double sided plated through hole. Stiffeners and rigidisers are an option which can help in handling during assembly and allows SMDs to be assembled to the product easier.

Click here to download a PDF of the Flexible Route Printed Circuits

Flexi-rigid Printed Circuits

A flex-rigid PCB is a multilayer circuit board sandwiching a flexible in between layers and having connections from rigid to flexible. Flex rigid PCB designs are heavily used in the aeronautical market where space and weight are an absolute premium. It can allow a large amount of components to be interconnected on more than one printed circuit board and then, folded into a smaller package to be slid into instrument cases and others alike.

Like using just a flexible to connect rigids, they offer a light weight solution, about half the weight of a rigid or a cable harness, to interconnections but with a permanent aspect that is much less susceptible to vibration and frequency related problems associated with aircraft. All the advantages that are out lined in the flexible write up apply to this product with the additional enhancements above.

The process route is complicated and requires a lot of tooling which has a significant impact on cost. However, if it the right product for the application, the reliability and space saving will outweigh the cost.

Click here to download a PDF of the Flex-Rigid Printed Circuits Route

Clarydon Electronic Services has a wealth of expertise in the design manufacture and supply of these products. Please do not hesitate to contact us should you need us to quote or simply for further information and advice.